Published on May 1, 2024

Understanding and Managing EHP in Shrimp

In this article, we delve into a damaging health challenge in the shrimp industry: EHP. To protect your operations, Kona Bay offers some key biosecurity practices in shrimp production, and we continue to invest in research trials related to increased robustness when faced with diseases such as EHP.

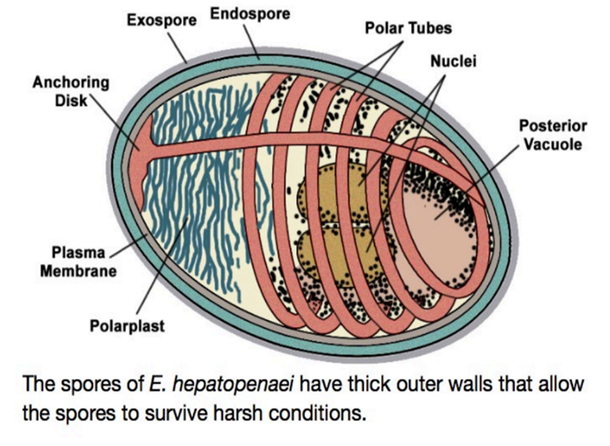

EHP (Enterocytozoon hepatopenaei) is a microsporidian parasite that has been a health challenge of focus for the shrimp industry. It disrupts digestion, causing slow growth and high size variation. EHP is currently widespread throughout China, Vietnam, Thailand, Malaysia, Indonesia, and India.

Enhancing robustness

Each part of the value chain can act in protecting shrimp stock from diseases such as EHP. As one of the leaders in breeding and genetics, we can take steps to increase natural robustness through the use of experimental challenges in dedicated laboratories and through sentinel trials where genetics are exposed to commercial conditions in farms.

Sentinel sites

Sentinel sites are used to measure the performance of our genetics within the typical conditions of a commercial farm. With these sentinel populations, we can compare which genetics are more robust when exposed to challenges. Currently, we are running sentinel populations in India and we expect to start in Indonesia soon. Sentinels will allow us to collect real time data on resistance to EHP and then feed this information back to our breeding program. We are also developing a lab test with controlled and extreme EHP pressure. In these trials, we will test which genetics are more robust to the presence of EHP. These results will be applied to our breeding program via genomic selection.

Proactive protection through biosecurity controls

Genetic selection is not the only solution to mitigate the risks associated with diseases, such as EHP. In all cases, genetics is part of the solution, and in general biosecurity measures are equally, if not even more, important. As it is applied to shrimp aquaculture, biosecurity may be defined as the practice of exclusion and/or implementation of mitigation strategies for specific pathogens from cultured aquatic stocks in broodstock facilities, hatcheries, and farms, or from entire regions and countries for the purpose of disease prevention/control.

Some of the most effective strategies used to prevent infectious disease are:

- Filtration and disinfection of source water

- Restricting movement of animals, personnel, and equipment

- Verification and use of pathogen free seed and feed sources

- Use of biosecure production systems

- Appropriate stocking densities to minimize stress and lower risk of infection

- Reducing the potential of disease introduction and transfer via animal vectors

- Restricting public access and movement of equipment between farms

- Effluent management to mitigate spread of disease

Management Strategies

There are a number of protocols for keeping EHP and other health challenges out of your operations. First, before stocking, ensure that the broodstock and post larvae (PLs) are screened for diseases. This can be done with the use of certified testing labs. Secondly, it is important to disinfect the ponds for pathogens before stocking. For different types of ponds, i.e. lined ponds or earthen pond bottoms, there are different protocols for disinfection. For earthen ponds, one strategy is to apply CaO (quick lime, burnt lime, unslaked lime or hot lime) at 6 tonnes/ha, plow the CaO into the dry pond sediment, and then moisten the sediment to activate the lime. Then leave for one week before drying or filling. After application of CaO, the soil pH should rise to 12 or more and then fall back to the normal range as it absorbs carbon dioxide and becomes CaCO3.

Lined ponds are very useful in maintaining a high level of biosecurity, although they come with a higher cost. Pictured below are examples of the process for disinfecting lined ponds. Regular cleaning and the daily release of sediments through a central drain are necessary practices to manage algae blooms and maintain water quality in shrimp ponds. Once the ponds have been stocked, be sure to conduct regular monitoring of your shrimp for growth, size variation, and EHP density in hepatopancreas.

Health risks are one of the biggest threats to shrimp farmers all over the world. By adopting proactive measures such as controls for people, equipment, and other outside vectors, cleaning and disinfection protocols, and regular monitoring, shrimp farmers can mitigate the risks of disease outbreaks. Continuous research and innovation in breeding technology will further enhance tolerance against emerging pathogens, contributing to a sustainable global shrimp industry.