Published on April 25, 2025

Ensuring excellence with rigorous monitoring and lab protocols in Indonesia

At Kona Bay Indonesia, shrimp broodstock production is supported by strict monitoring systems and laboratory protocols designed to ensure quality, health, and biosecurity at every step of the process. From water quality to health checks and export preparation, every detail is meticulously managed to guarantee reliable, high-performing broodstock for the global shrimp industry.

Daily water monitoring and weekly lab insights

Water quality is central to shrimp health. That’s why Kona Bay conducts twice-daily checks of key parameters like dissolved oxygen, pH, and temperature across both grow-out and quarantine systems. These measurements are complemented by weekly lab tests that go deeper, analyzing microbiological balance, bacterial activity, and mineral composition. Together, these routines create an environment where shrimp can thrive, minimizing stress and preventing potential outbreaks.

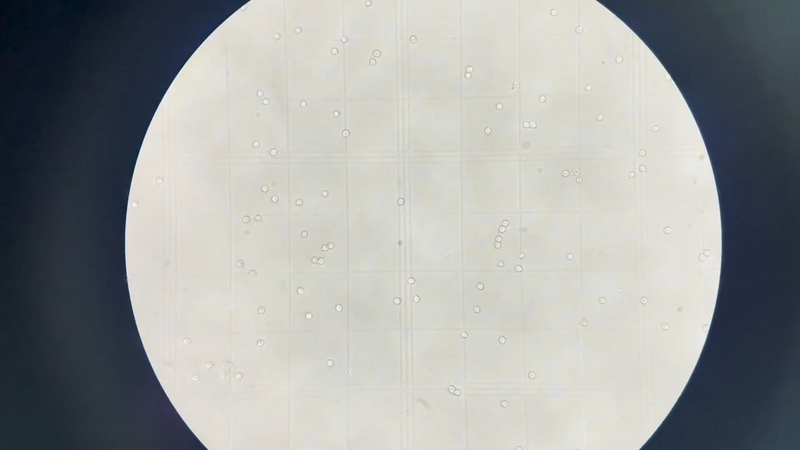

Precision in reproductive monitoring

Reproductive performance is monitored closely through weekly sperm quality assessments. Each week, three batches of broodstock, ranging in age from 17 to 28 weeks, are evaluated with an additional round of checks conducted right before animals are prepared for shipment. This consistent monitoring ensures optimal fertility and reliability for hatcheries that rely on Kona Bay’s stock.

A Proactive stance on biosecurity and environmental safety

Every month, the environment within the facility is assessed to ensure it meets strict internal and external standards. Biosecurity screenings are carried out to identify and mitigate any risks that could compromise animal health. This proactive stance helps Kona Bay maintain its Specific Pathogen Free (SPF) status, a critical requirement for responsible shrimp farming.

Meeting international health standards

Health checks aren’t just internal, they’re also aligned with government requirements. Kona Bay performs official monthly evaluations, especially when preparing shipments to market with strict import regulations like Australia and Arizona. These assessments provide assurance that the animals are healthy, compliant, and ready for international transport.

Assessed to the last detail

Before each shipment, every broodstock is examined individually. The evaluation includes physical condition, coloration, maturity, and genetic background, ensuring that each animal matches both Kona Bay’s high standards and the specific needs of its customers.