Published on July 30, 2024

The Basics of Biosecurity and Pond Health Management for Shrimp Farming

Health challenges are one of the biggest elements limiting the growth and sustainability of the shrimp industry. Healthy shrimp populations ensure consistent production and market stability for all members of the value chain.

Diseases such as EHP, White Spot Disease (WSD), White Feces Syndrome (WFS) can quickly spread and cause reduced FCR, negatively impact crop quality, and lead to significant mortality adding to substantial economic losses. Maintaining stringent biosecurity measures helps prevent the introduction and spread of these pathogens.

Understanding Biosecurity

As it is applied to shrimp aquaculture, biosecurity is defined as the practice of exclusion and/or implementation of mitigation strategies for of specific pathogens from cultured aquatic stocks in broodstock facilities, hatcheries, and farms, or from entire regions and countries for the purpose of disease prevention/control.

Biosecurity is a key concept that must be understood and implemented at all levels of the production chain in order to realize the full genetic potential of specific pathogen free (SPF) stocks. In some cases, where exclusion is not possible, biosecurity may also relate to disease management strategies.

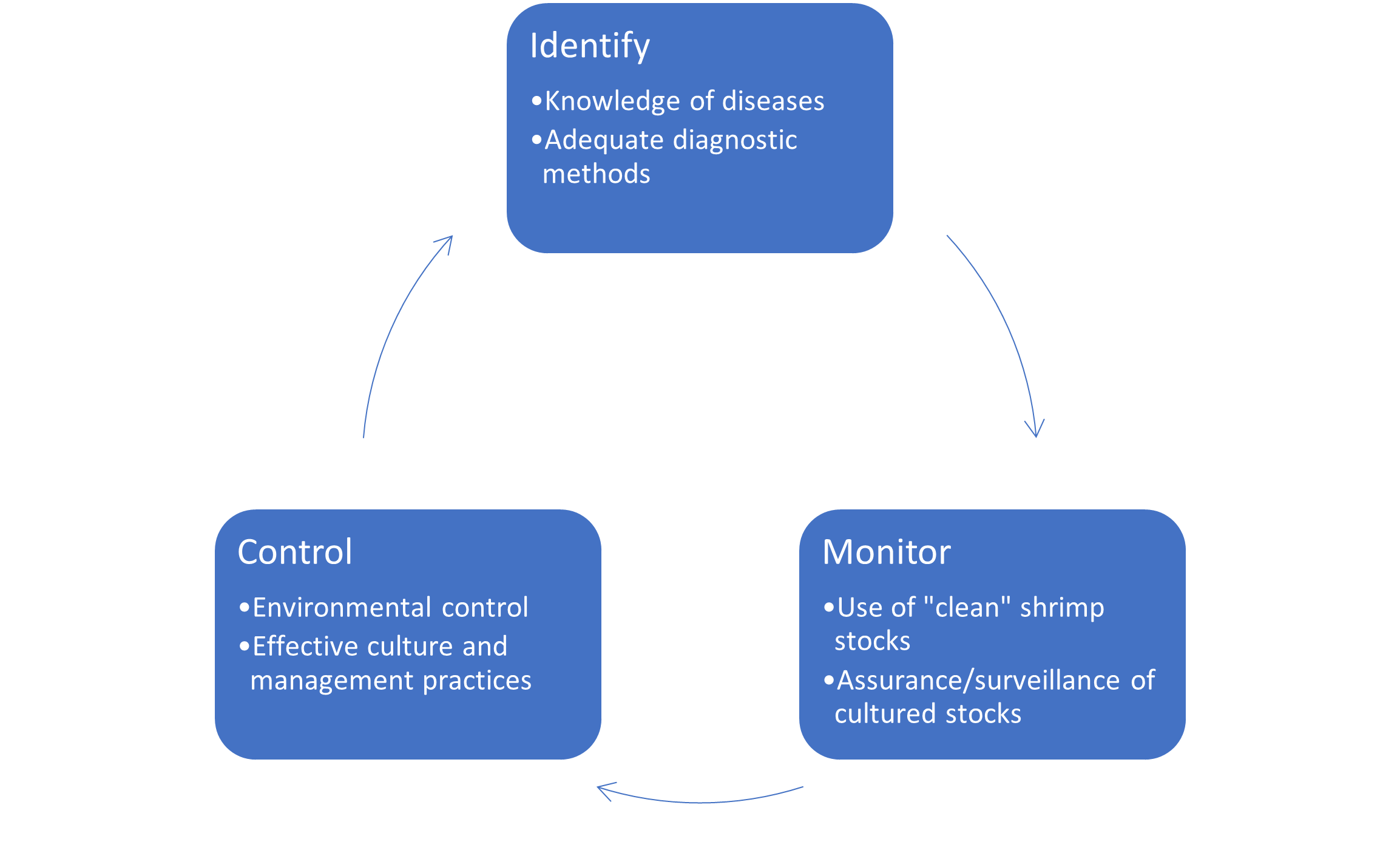

Key components of biosecurity involve identifying, monitoring, and controlling for various types of pathogens.

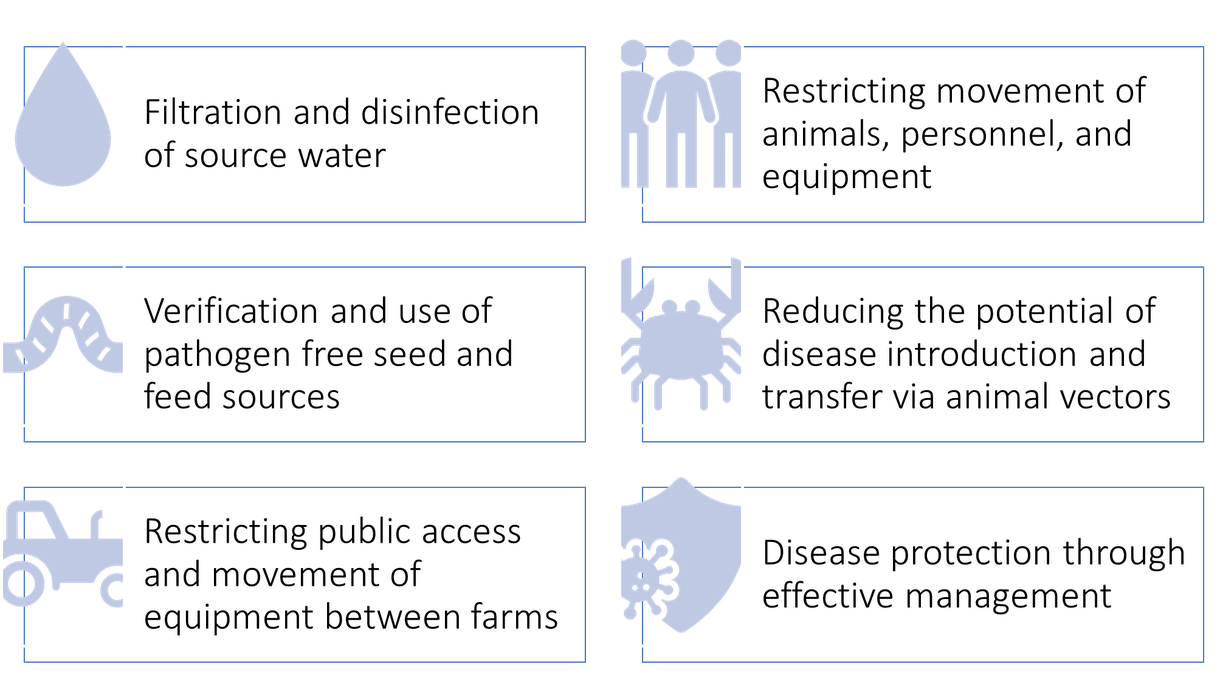

Below are some of the most effective disease control measures.

When it comes to practical management tips, pond health management is one crucial area of importance.

Pond health management

Pond health management can include cleaning and disinfection, water quality, appropriate stocking density, and implementation of proper feeding strategies aimed at promoting shrimp health. Application of probiotics and pond microbial management are also important considerations.

Cleaning & Disinfection

For different types of ponds, i.e. lined ponds or earthen pond bottoms, there are different protocols for disinfection. For earthen ponds to mitigate infection by EHP for example, one strategy is to apply CaO (quick lime, burnt lime, unslaked lime or hot lime) at 6 tonnes/ha, plow the CaO into the dry pond sediment, and then moisten the sediment to activate the lime. Then leave for one week before drying or filling. After application of CaO, the soil pH should rise to 12 or more and then fall back to the normal range as it absorbs carbon dioxide and becomes Calcium Carbonate (CaCO3).

Lined ponds are very useful in maintaining a high level of biosecurity, although they come with a higher cost. Liners are used on the bottom and sides of the pond to stop contact from acid-sulfate soils. This helps keep the pH levels from getting too low, especially during rainy seasons. Liners also make pond cleaning and preparation faster, taking just a week, compared to earthen ponds, which can take a month or more to dry out the soil.

Strategic aeration of lined ponds can be another effective management strategy to collect bottom sludge for easier removal. Accumulation of organic matter can be the cause of many shrimp health-related issues. These issues may be minimized by effective placement of aerators/paddlewheels creating current and pond water mixing. Nano-bubble technology can be helpful to increase dissolved oxygen levels, which is important to support shrimp health/biological functions. It also has anti-microbial properties, which may improve water quality and the efficiency of chemical, biological and physical processes. This has the potential to reduce the use of harmful chemicals and other inputs.

Water quality

Below are some general water quality parameters to keep in mind during the growth stage, but variation is possible depending on the system, pond size, and environment. Extreme changes in salinity, temperature, and pH create a stressful environment for the shrimp and can act as disease triggers.

- Temperature range: 27.0 to 32 C

- Salinity range: 5 to 32ppt

- pH: 7.8-85, daily fluctuations not to exceed 0.5

- Alkalinity: 119-150 ppm

- Flow-through water exchange: 20%/day for lined ponds, no daily water exchange for large earthen ponds unless required (or possibly every 40-60 days, depending on WQ).

- Filtered and sterilized (using UV, ozone, or chlorine systems)

Stocking density

In summary, health and biosecurity are foundational to the success and sustainability of the shrimp industry. By focusing on key management practices and understanding the basics of biosecurity, shrimp farmers can mitigate the risks of disease outbreaks. Kona Bay is committed to ongoing research and advancements in breeding technology to enhance robustness and support shrimp farmers with the knowledge and tools to help them succeed.